We provide a pre-engineered steel building and steel structure construction solution with a strong commitment to quality and progress. In particular, consulting is the first important step to give our customers the solution that best suits your needs. The consultation process is a tight two-way interaction between our consultant team and our customers. In which, we will base on project’s features to propose:

We not only give consulting on steel structure solutions but also related items of the project such as foundation structure, equipment installation solutions ...

Many factors affecting the construction and equipment installation will be considered such as:

which is capable of improving efficiency, saving energy and operation costs. At the same time, the project has a potential life expectancy of 50-70 years.

In this process, ASI consulting team will estimate, process and allocate cost in the most appropriate and logical way. We will make estimates of the quantity and price of all the resources you need in order to finish the project. From there, ASI helps investors have an overview of the project and have a good preparation of resources for the project.

With extensive experience in the design, manufacturing and erection of many projects, we will give accurate estimates of the time required to complete the project. Therefore, we could complete commitments on progress and quality with customers.

After ASI and customers agree on project solutions, project schedule and plan, the design phase will start.

Based on agreed terms from phase 1 - Consulting, ASI engineer team will carry out the design phase based on the latest American and European pre-engineered steel buildings and steel structures, including:

shows what technical elements the building will have, as well as technical materials for each different component. Technical design is the backbone of the project. The results of this stage are architectural drawings and steel structure drawings

this stage provides production drawings so that the factory can fabricate accurately components and accessories. The drawings from the technical stage will be transferred to production drawings. The production drawing should show fully and in detail the size, quantity, shape, and technical specifications of each component.

Erection drawings describe site plans, erection phase diagram and erection requirements with good access to the erection location. Pre-engineered steel building and steel structure requires high erection accuracy to ensure sustainable construction.

ASI Design team with high expertise and rich experience will offer optimal design solutions to bring the highest quality and the most cost-efficient building solutions for our customers. We utilize cutting-edge contemporary engineering softwares for structural analysis and detailing. During more than 1 years, ASI has successfully designed projects in Vietnam and supplied steel structures for export to many regions around the world. We are capable of providing optimal solutions for many types of projects such as factories, warehouses, industrial buildings, commercial centers, public buildings...

We always update cutting-edge contemporary engineering software in pre-engineered steel buildings and steel structure design: SAP 2000 or ETAB, CFS purlin design, Tekla which is used to design production and erection drawings. Designed according to American design standards MBMA (Technical guidance on steel building system), AISC (Technical guidance on steel structures, Allowable Stress Design).

Manufacturing process has three separate stages to manufacture three main constituting components including:

Primary members:column, beam

purlin, door…

roof sheet, wall cladding, flashing…

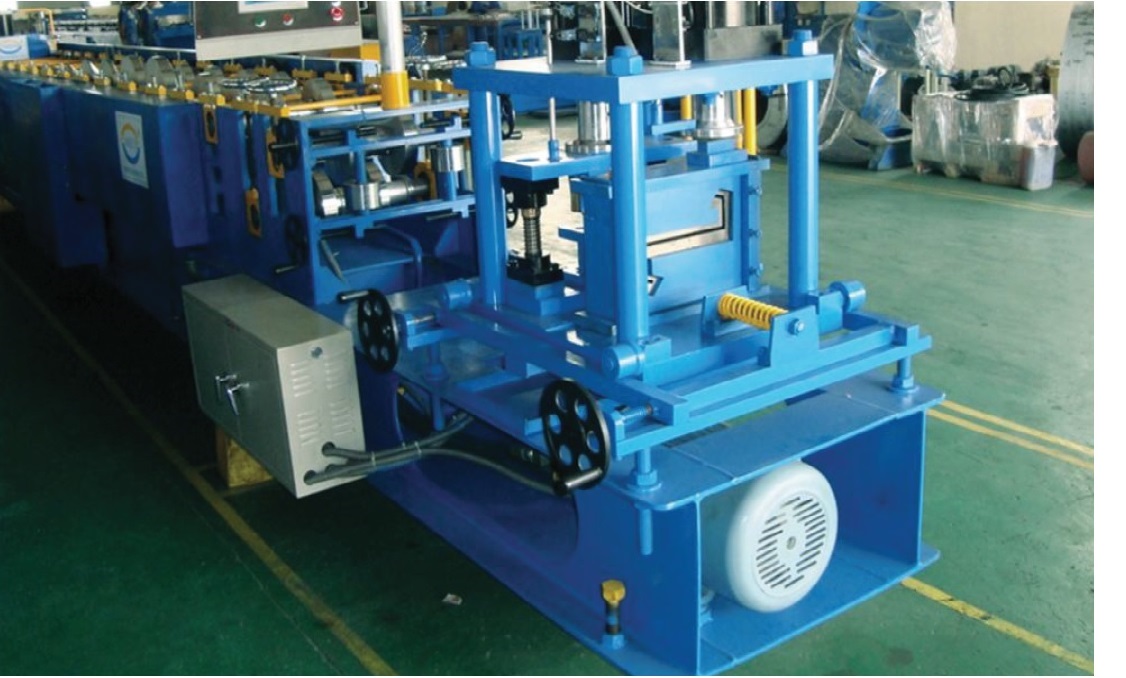

Equipment and machines:

Machine: Purlin Rolling Machine

Erection of

pre-engineered buildings and steel structureis the last step in our building process that all the components from the previous steps come together.

Step 1: Prepare before erection

Check the erection equipment, and materials, including: quantity, safety, quality…

Step 2: Erect column and bracings

The intermediate or interior frames nearest the bearing endwall are usually erected first. This bay usually contains the diagonal bracing. Erect the columns first, tie them together with the sidewall girts and tighten the anchor bolts. Tie all the temporary bracings before releasing the crane load.

Step 3: Erect rafter

After the columns have been erected, the ground-assembled rafter is hoisted into place and connected to the columns. The rafters are assembled on the ground that need to install the flange braces & tighten the splice joints. The flange brace should be bolted to the rafter prior to raising in order to save time. Lift & erect the rafter assembly, ensure to tie enough guy wire ropes & tag lines.

Step 4: Install purlins and girts

Galvanized steel purlins are usually formed in shapes C, Z ... with purlins distance from 1m - 1.5m. Purlins are linked to the main steel frame to support the roof system. All purlins, girts, and eave struts are installed in the braced bay and the entire bay plumbed, aligned and braced before proceeding further. If the building is designed without cable bracing, the erector is responsible for providing temporary erection bracing.

Step 5: Calibrate the first frame

Step 6: Erect next frame

Step 7: Complete installation for the rest frame

Step 8: Erect roof monitor

Step 9: Check completion before covering

Step 10: Erect covering and finish